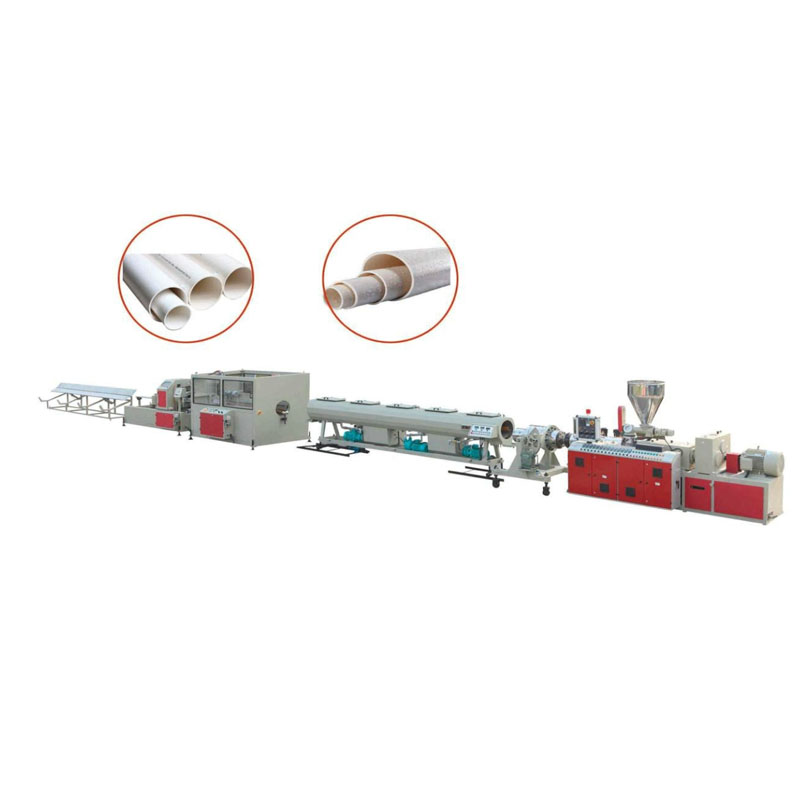

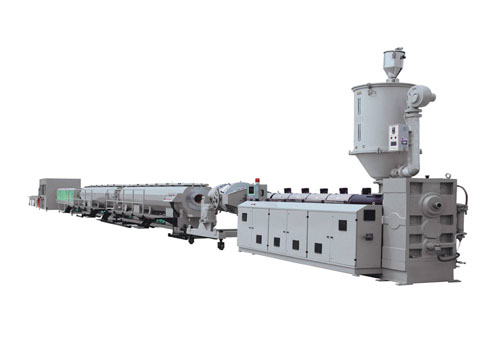

1, PVC pipe extrusion line(PVC/UPVC/CPVC)

Introduction:

GF series plastic pipe extrusion line is mainly used in the area of agricultural water supply system, architectural water supply system, pavement of cables.. .etc. as well as PVC pipe material of all sorts of pipe caliber and wall thickness. This machine group consists mainly of twin conical (parallel) Screw extruder, vacuum calibration tank, haul-off unit, cutting unit, tilter.. etc. The Screw extruder and haul-off unit have applied imported A/C inverter; both vacuum pump and driving motor have applied excellent products. The drawing machine includes two-claw type, three-claw type, four-claw type, six-claw type, eight-claw type…etc..

Sawing cutting or planet cutting can be applied, it is additionally applied with length measuring meter and thickness increasing device, the property of machine group is reliable, the production efficiency is high. With special device, it can produce inner wall spiral pipe, inner wall hollow pipe, and core layer foam pipe…etc. it can also produce PP,PE,ABS.PPR,PEX, silicon core pipe and pipe of other material. The planetary cutting machine is fully automatic computer digital control; it has such advantages of simple operation, reliable property, etc. It has reached world advanced level.

Main technical parameter:

1, Exturder model: SJZ65/132 ; SJZ65/132 ; SJZ65/132 ; SJZ80/156 ; SJZ80/156 ; SJZ92/188 ; SJZ92/188

2, Pipe diameter: 32-100mm ; 63-200mm ; 63-110mm ; 110-250mm ; 200-400mm ; 315-630mm ; 400-1000mm

3, Die head: Single outlet

4, Down-stream machine: Vacuum water tank/Cooling water tank/Haul-off unit/Planetary cutting unit/Stocker

5, Total power: 85kw ; 86.5kw ; 85kw ; 114kw ; 131kw ; 220kw ; 500kw

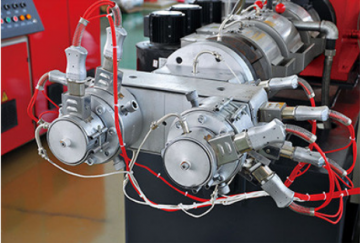

2, PVC pipe extrusion line(double pipe)

Introduction:

GF series plastic pipe extrusion line is mainly used in the area of agricultural water supply system, architectural water supply system, pavement of cables.. .etc. as well as PVC pipe material of all sorts of pipe caliber and wall thickness. This machine group consists mainly of twin conical (parallel) Screw extruder, vacuum calibration tank, haul-off unit, cutting unit, tilter.. etc. The Screw extruder and haul-off unit have applied imported A/C inverter; both vacuum pump and driving motor have applied excellent products. The drawing machine includes two-claw type, three-claw type, four-claw type, six-claw type, eight-claw type…etc..

Sawing cutting or planet cutting can be applied, it is additionally applied with length measuring meter and thickness increasing device, the property of machine group is reliable, the production efficiency is high. With special device, it can produce inner wall spiral pipe, inner wall hollow pipe, and core layer foam pipe…etc. it can also produce PP,PE,ABS.PPR,PEX, silicon core pipe and pipe of other material. The planetary cutting machine is fully automatic computer digital control; it has such advantages of simple operation, reliable property, etc. It has reached world advanced level.

Main technical parameter:

1, Exturder model: SJZ65/132 ; SJZ80/156

2, Pipe diameter: 16-63mm ; 63-110mm

3, Die head: Double outlet

4, Down-stream machine: Vacuum water tank/Cooling water tank/Haul-off unit/Planetary cutting unit/Stocker

5, Total power: 85kw ; 136kw

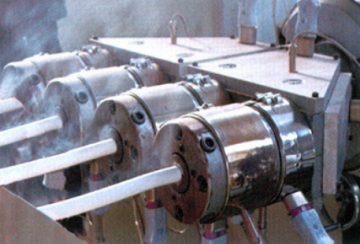

3, PVC pipe extrusion line(four pipe)

Introduction:

GF series plastic pipe extrusion line is mainly used in the area of agricultural water supply system, architectural water supply system, pavement of cables.. .etc. as well as PVC pipe material of all sorts of pipe caliber and wall thickness. This machine group consists mainly of twin conical (parallel) Screw extruder, vacuum calibration tank, haul-off unit, cutting unit, tilter.. etc. The Screw extruder and haul-off unit have applied imported A/C inverter; both vacuum pump and driving motor have applied excellent products. The drawing machine includes two-claw type, three-claw type, four-claw type, six-claw type, eight-claw type…etc..

Sawing cutting or planet cutting can be applied, it is additionally applied with length measuring meter and thickness increasing device, the property of machine group is reliable, the production efficiency is high. With special device, it can produce inner wall spiral pipe, inner wall hollow pipe, and core layer foam pipe…etc. it can also produce PP,PE,ABS.PPR,PEX, silicon core pipe and pipe of other material. The planetary cutting machine is fully automatic computer digital control; it has such advantages of simple operation, reliable property, etc. It has reached world advanced level.

Main technical parameter:

1, Exturder model: SJZ65/132 ; SJZ65/132

2, Pipe diameter: 16-32mm ; 16-63mm

3, Die head: Four outlet

4, Down-stream machine: Vacuum water tank/Cooling water tank/Haul-off unit/Planetary cutting unit/Stocker

5, Total power: 85kw ; 91kw

4, PVC steel-wire hose extrusion line

Introduction:

The machine is used to produce PVC steel wire reinforced transparent pipes. The pipe wall is made of transparent PVC plastic. In the pipe inner-wall, there are spiral steel wire. The kind of pipe has the advantage of extrusion resistance, corrosion resistance, static electricity resistance, anti-high pressure and good running. It is suitable for the conveying high pressure or combustible gas and liquid, heavy suction and delivery of liquid sludge. It is mainly used in fields machinery, such as chemical industry, building, irrigation and vacuum pumps,etc.

Main technical parameter:

1, Extruder model: SJ45/30 ; SJ65/30 ; SJ90/30 ; SJ120/30

2, Pipe diameter: 12-25mm; 20-50mm; 50-102mm ; 75-150mm

3, Output: 20-40kg/h ; 40-75kg/h ; 70-130kg/h ; 100-150kg/h

4, Total power: 35kw ; 40kw ; 50kw ; 75kw

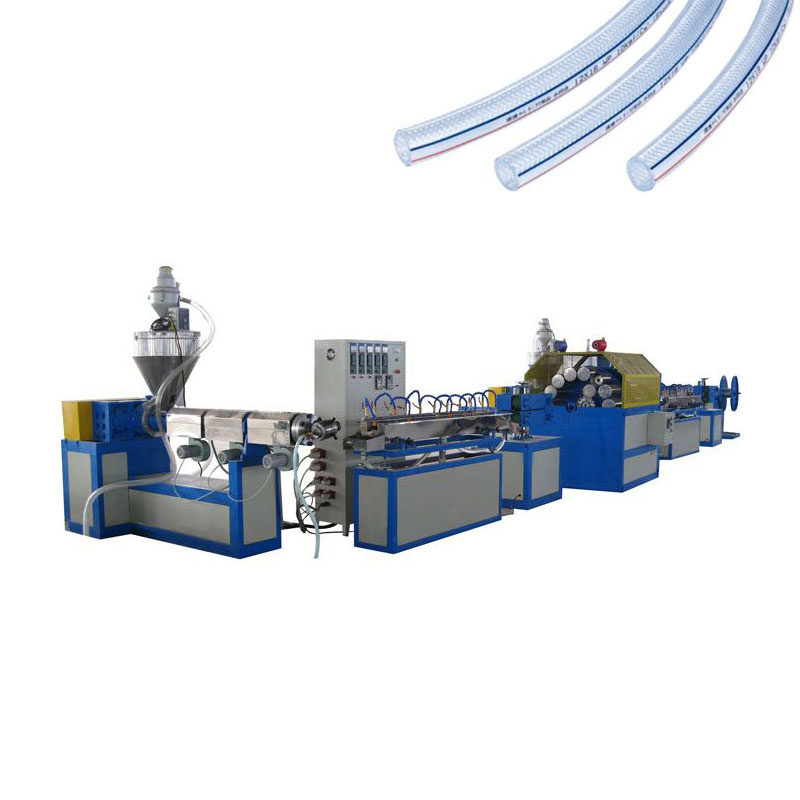

5, PVC Fiber reinforced hose extrusion line

Introduction:

This unit is used for to produce PVC fiber reinforced hose, also named as PVC net hose, commonly called as snake hose. This kind of soft hose is non-toxic, transparent, pressure resistance, tensile resistance, acid resistance, corrosion resistance, beautiful appearance, soft and lightweight, durable. Suitable for pressure corrosive gas, liquid transporting, widely used in machinery, coal, petroleum, chemical industry, agricultural irrigation, construction, civil (solar heater, gas tank etc) and other fields. Now also used in a large number of gardens, lawn watering.

This line consists of main extruders, water cooling tank, haul off machine, fiber braiding machine, coiler etc, which has reasonable design, unique structure, stable performance, easy operation and maintenance, constant production capacity, warmly welcomed by customers.

Main technical parameter:

1, Extruder model: SJ45/30 ; SJ55/30 ; SJ65/30 ; SJ75/30

2, Pipe diameter: 6-16mm; 8-25mm; 12-50mm ; 20-50mm

3, Output: 20-40kg/h ; 30-60kg/h ; 40-80kg/h ; 60-110kg/h

4, Total power: 35kw ; 42kw ; 50kw ; 65kw

6, PVC/PE single-wall corrugated extrusion line

Introduction:

PE, PVC, PP pipes PE corrugated pipe production line adopts single screw extrusion production line, and the raw materials are PE, PP and PVC particles. The PVC corrugated pipe extrusion production line adopts a twin-screw extrusion production line, and the raw material is PVC powder. 6-25mm PE, PVC corrugated pipe, using water cooling method, the speed can reach 30 meters/minute, the machine life is 8-10 years. Advantages: First of all, this corrugated pipe extrusion production line can be used to produce PE PP PVC PA corrugated pipes. 2. The extrusion production line includes: vacuum feeder, hopper dryer, SJ45 single-screw extruder, die head, molding module, molding machine, and double-disc winder. Third, we can customize the machine according to samples or drawings of customer products.

Main technical parameter:

1, Extruder model: SJ45/30 ; SJ45/30 ; SJ50/30 ; SJ65/30 ; SJ75/30

2, Pipe diameter: 4.5-9mm; 10-32mm; 10-32mm ; 32-63mm ; 63-110mm

3, Output: 8-15kg/h ; 40kg/h ; 50kg/h ; 120kg/h ; 140kg/h

4, Speed: 5-12m/min ; 5-10m/min ; 15-25m/min ; 7-15m/min ; 1-6m/min

5, Mold quantity: 38 pairs ; 38 pairs ; 90 pairs ; 66 pairs ; 66 pairs

6, Total power: 11kw ; 11kw ; 15kw ; 18.5kw ; 37kw

7, HDPE pipe extrusion line

Introduction:

PE series plastic pipe extrusion line is mainly used in the area of agricultural water supply system, architectural water supply system, pavement of cablesjetc. This machine group consists mainly of vacuum calibration tank, .haul-off unit, cutting unit, tilterjetc. Single screw extruder and haul-off unit have applied imported A/C inverter; both vacuum pump and driving motor have applied excellent products. The haul-off unit includes two-claw type, three- claw type, four-claw type, six-claw type, eight-claw type, ten-claw type, twelve claw type…etc.

No-scraps cutting, saw cutting or planetary cutting can be applied, the property of machine group is reliable, the production efficiency is high. With special device, it can produce inner wall spiral pipe, inner wall hollow pipe, and core layer foam pipejetc. it can also produce PP,PE,ABS,PPR,PEX, silicon core pipe and pipe of other material. The planetary cutting machine is fully automatic computer digital control; it has such advantages of simple operation, reliable property, etc. lt has reached world advanced level.