1, Single screw extruder

Introduction:

SJ series single screw extruder has advantages of high output, excellent plasticization, low energy consumption, stable running. The gearbox of single screw extruder adopt high torque gear box, which has features of low noisy, high carrying capacity, long service life; the sccrew and barrel adopt 38CrMoAlA material, with nitriding treatment; the motor adopt Siemens standard motor; inverter adopt ABB inverter; temperature controller adopt Omron/RKC; Low pressure electrics adopt Schneider electrics.

By different requirement, SJ series single screw extruder could be designed as PLC touch screen control type extruder and panel control type extruder. The screw could adopt high speed screw to achieve more output.

Advantage:

1, world famous brands major parts: SIEMENS motor, ABB/FUJI/LG/OMRON inverters, SIEMENS/Schneider contactors, OMRON/RKC temperature controllers, DELTA/SIEMENS PLC system

2, Experience engineers all with passports ready for customers services.

3, The electrical system has mainly applied imported parts, it has multiple alarm system, and there are few problems which can be easily eliminated. The cooling system has applied special design, heat emission area is enlarged, the cooling is rapid, and temperature control tolerance can be ± 1 degree.

2, Conical twin-screws extruder

Introduction:

Model SJZ series twin conical screw extruder is a kind of special equipment for extruding PVC powder. With different sorts of molds and auxiliary machines, i can produce all sorts of PVC plastic pipe material, profiled material, board material, sheet material, bar material and granulation.

The screw has applied oil cooling system. Barrel is cooled by special wind cooling system. The system has applied special computer control. According to customer’s requirements, most reasonable screw can be made so as to achieve best plasticity state and material quality. The screw is made by high precision special digital screw miller; extruding property can be highly harmonized. It has firstly introduced advanced technique of producing screw with variable pitch and depth, so that the material can be more softly sheared and cut. The distribution box is specially designed, pull force bearing is fully imported, and the drive life span can be prolonged. It can bear larger extruding pressure. The electrical system has mainly applied imported parts, it has multiple alarm system, and there are few problems which can be easily eliminated. The cooling system has applied special design, heat emission area is enlarged, the cooling is rapid, temperature control tolerance can be±1℃ .

Main technical parameter:

1, Model: SJZ45 ; SJZ51 ; SJZ55 ; SJZ65 ; SJZ80 ; SJZ92 ; SJZ110

2, Screw diameter: 45/90(mm) ; 51/105(mm) ; 55/110(mm) ; 65/132(mm) ; 80/156(mm) ; 92/188(mm) ; 110/220(mm)

3, Main motor: 15kw ; 18.5kw ; 22kw ; 30/37kw ; 55kw ; 110kw ; 160kw

4, Capacity: 120kg/h ; 150kg/h ; 180kg/h ; 300kg/h ; 450kg/h ; 900kg/h ; 1400kg/h

5, Centre height: 1000mm ; 1000mm ; 1000mm ; 1000mm ; 1000mm ; 1150mm ; 1200mm

6, Net weight: 3000kg ; 3000kg ; 3500kg ; 4000kg ; 5000kg ; 8000kg ; 12000kg

7, Dimension: 3.3×1.2×2.1(m);3.6×1.2×2.1(m); 3.3×1.2×2.1(m) ; 4.5×1.5×2.4(m) ; 4.7×1.5×2.4(m) ; 6×1.6×2.5(m) ; 5.4×1.8×3.0(m)

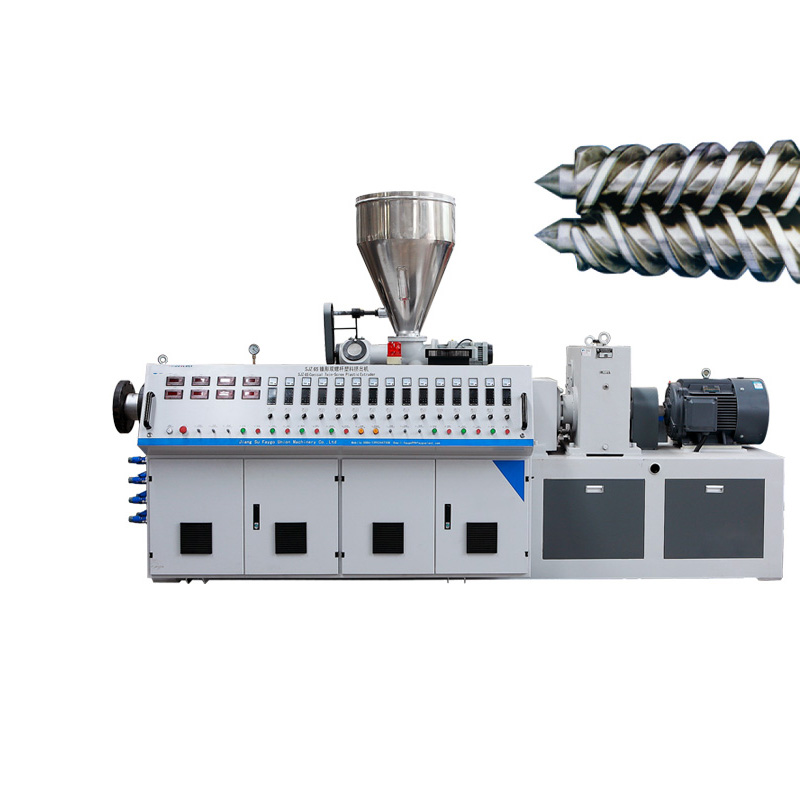

3, Parallel twin-screws extruder

Introduction:

Model SJP serials twin parallel screw extruder is a kind of special equipment for extruding of PVC powder. With different sorts of molds and auxiliary machines, it can produce all sorts of PVC plastic pipe material, profiled material, board material, sheet material, bar material and granulation.

The screw has applied oil system. Barrel is cooled by special wind cooling system. The control system has applied computer control. According to customer’s requirements, most reasonable screw can be made so as to achieve best plasticity state and material quality. The screw is made by high precision special digital screw miller, extruding property can be highly harmonized. It has firstly introduced technique of producing screw with variable pitch and depth, so that the material can be more softly sheared and cut. The distribution box is specially designed, pull force bearing is fully imported, and the drive life span can be prolonged. It can bear larger extruding pressure. The electrical system has mainly applied imported parts, it has multiple alarm system, and there are few problems which can be easily eliminated. The cooling system has applied special design, heat emission area is enlarged, the cooling is rapid, temperature control tolerance can be±1℃ .

4, Co-extrusion extruder

Introduction:

JH series back & forth single screw co-extruder is developed and imported the lasted German technique, easy operation and have a wide range use for different material, it is mainly used for color extrusion and sealing joint strip co-extrusion of profiled, and polyolefin Pipe color Co-extrusion.